Fully-New Full Automatic Soft Carbonated Drink Craft Beer Canning Water Drink Bottle Liquid Filling Capping Machine (BCGF series)

Basic Info

| Model NO. | BCGF series |

| Feed Cylinder Structure | Single-Room Feeding |

| Dosing Device | Capacity Cup |

| Filling Principle | Pressure |

| Packaging Container Lifting Structure | Pneumatic Lifting |

| Structure | Rotary |

| Packaging | Bottle |

| Packaging Material | Film |

| Production Name | Beer Filling Machine |

| Transport Package | Iron Tray or Wooden Case |

| Specification | CE, ISO9001 |

| Trademark | SINO-TECH |

| Origin | Made in China |

| HS Code | 8479820090 |

| Production Capacity | Depending on Your Sample |

Product Description

China supplier of Beer filling machine(BCGF series)This Beer Filling Machines is my company's introduction of German technology, combined with the characteristics of beer production industry, designed to develop small-scale beer filling equipment. The Beer Filling machines has excellent mechanical operation reliability, improved rinsing, filling, cover screwing, disinfection sterilization and other functions.

Product Description

Structural Features

1, The rinsing machine using high-strength stainless steel bottles of spring-loaded folders, to ensure a stable reversal of the glass bottles. The nozzle is a plum-like structure can wash every corner of the sidewall and bottom to make the bottle clean.2, Filling machine with spring-type mechanical lifting equipment to upgrade glass bottles, large bearing support floundering in the vat and use of guide-rod in the orientation of the structure, there are pre-cover features.

3, Using high-precision mechanical filling valve, with cylinder liquid level and the back pressure controlled by a variable signal proportional. Fast, stable, accurate, to be vacuum one at a time.

4, Stainless steel plunger and mechanical stirring gland-type magnetic reasonable cap to ensure that the gland is healthy and reliable. Hopper and the cap taking- cover, capping transmitted by magnetic. The capping is reliable and automatic unloading, reducing the rate of broken bottles.

5, Before the capping, use hot water bubble set to displace bottlenecks air, ensuring the oxygen content of less than 0.15mg / L.

6, Filling machines includes broken bottle automatically stopping valve, broken bottle washing, and foam automatically exhausting device.

7, with perfect CIP cleaning function, and capable of rinsing filling pipes with acid, lye liquid and hot water.

8, All the materials in contact with the valves, tanks, pipes are made of stainless steel 304 materials, inside and outside the wall of mirror-polished, ensuring it is healthy.

9, Manually dry oil lubrication system to make sure equipment maintenance is more convenient.

10, The whole operation adopts advanced man-machine interface, PLC control, frequency conversion stepless speed regulation and other automatic control technology, with no bottle no open valves, no stamps; No cap no operation, and other security protection.

Rinser is special equipment for glass bottle, using unique bottle clamp filling technology, frequency speed control, tank liquid level control, balanced pressure filling. Contact with the material part of the material are stainless steel 304 material: Pipe system control components are imported component parts.

Rinser Rotary, reversal washing bottle; Rinsing bottle time adjustable; A medium (sterile water) rinsing bottle; Or by the user-defined rinsing bottles of medium, smooth and reliable operation, plum-shaped nozzle, rinsing is fully clean.

Product Parameters

| Model | BWFC14-12-4 | BWFC18-18-6 | BWFC24-24-8 | BWFC32-32-10 | BWFC40-40-12 | BWFC50-50-15 | BWFC60-60-18 |

| Washing heads | 14 | 18 | 24 | 32 | 40 | 50 | 60 |

| Filling heads | 12 | 18 | 24 | 32 | 40 | 50 | 60 |

| Capping heads | 4 | 6 | 8 | 10 | 12 | 15 | 18 |

| Applicable bottle | Bottle diameter(mm): 50-90 Bottle height(mm): 150-310 | ||||||

| Applicable cap | Crown cap | ||||||

| Capacity | 1500-2000 | 4000 | 6000 | 8000 | 10000 | 14000 | 16000 |

| Main machine Motor(KW) | 1.5 | 2.2 | 4 | 5.5 | 7.5 | 11 | 15 |

| Overall dimensions(mm) | 1850x1650x2750 | 2360x1880x2750 | 2670x2200x2750 | 4050x2290x2750 | 3800x3000x2850 | 5400x3350x2850 | 5560x3550x2850 |

| Weight(kg) | 3200 | 3800 | 4200 | 5200 | 6700 | 8500 | 10600 |

Application

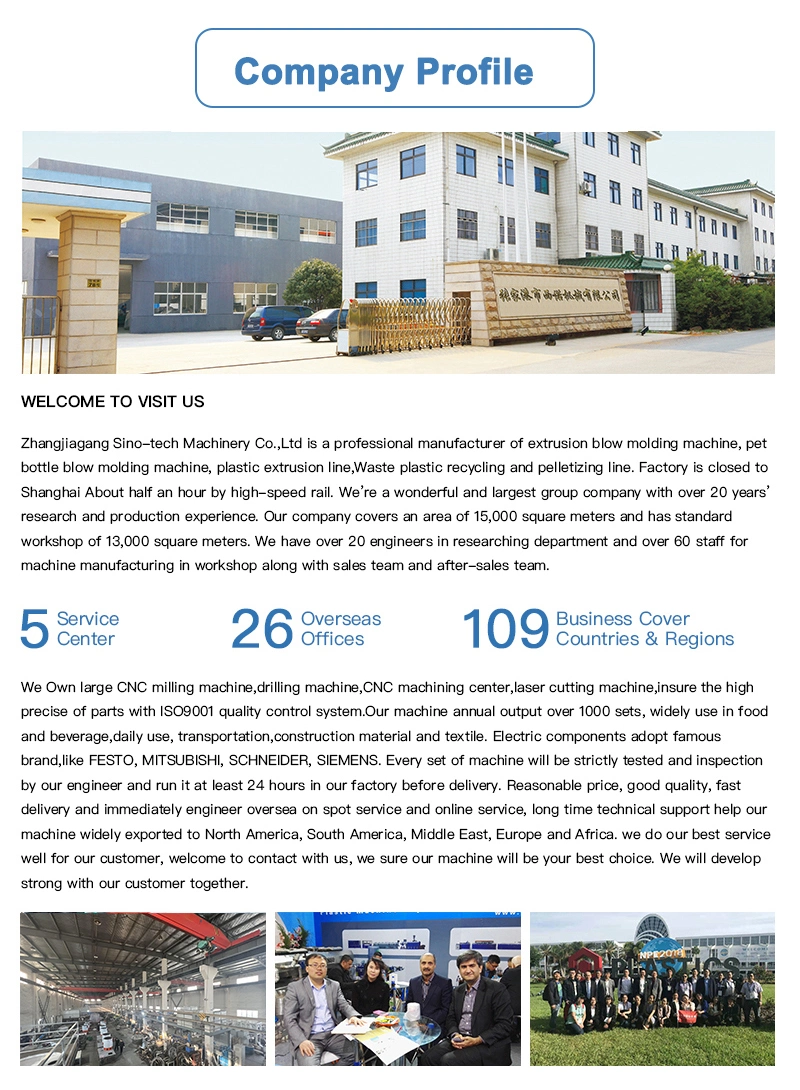

Company Profile

FAQ

Q: Can we visit your factory?

Sure. We located in Zhangjiagang city which is very near Shanghai. For overseas customers, you can fly to Shanghai Pudong International Airport. We can pick you up in the Airport. (or Hongqiao International Airport. ) We also provide visit online by video.

Q: How can we get the exact price of plastic machine?

Contact us with the products size, shape, annual quantity and photo if possible. We can recommend our machine models with quotation.

Q: Do you provide any spare parts with machine?

Yes, we offer all necessary spare parts before shipment.(contact us for packing list )

Q: How about your after-sale service ?

We offer manual instruction and engineer training before loading,after shipment we provide 24 HRS online support, video technical support or field installation assist.

Q: What is the lead time?

For customized machine, it takes about 45-60 days after deposit. For stock machine, fast shipment. ( The actual production cycle will vary according to the degree of customization.)

Q: What is the warranty period for your machine ?

12 months warranty for components and technical support .

Q: Do you provide custom machines?

Most of our machines are customized. Our goal is efficiency and stable performance. We design the machines according to customers products to meet customer' needs.

Q: How can we install the machine when it arrives?

We can send experienced technicians to customer's country for guiding the installation and commission the machine, also train the customer's employees.

Q: What's the advantage of SINOTECH?

We provide customers with turnkey projects. Including plant design, plastic machine and mold installation, debugging, also we can source the auxiliary equipments for customers. We can ship the full set of machines after testing in our factory. It will save a lot of cost and time

Any question,please call me.